Since I bought my first milling machine, I planned to convert it to a CNC mill.

For many years it were only plans, but now I finally started to buy the parts I'm going to need.

I sold my old mill and bought a new Sieg X2 Mini mill:

|

|

Clickbank Guide & Tools

Clickbank Guide & Tools

|

Specifications |

|

| Drilling capacity |

13 mm |

End mill capacity |

16 mm |

Face mill capacity |

30 mm |

Headstock travel(Z) |

180 mm |

Cross axis(X) |

100 mm |

Longitudinal axis(X) |

220 mm |

Spindle rotary angle |

-45¡ã-+45¡ã |

Output power |

350 W |

| Spindle taper |

MT#3 or R8 |

Spindle speed |

| low range |

0-1100 rpm ¡À10% |

| High range |

0-2500 rpm ¡À10% |

|

T-slot |

12 mm |

| Weight(net/gross) |

50/68kg |

| Packing size(LxWxH) |

540*500*760 mm |

| |

|

| |

|

|

|

|

A HOBBYCNC PRO Chopper Driver Board Kit from www.hobbycnc.com, complete with Nema 23 stepper motors.

|

|

Specifications:

- 3 or 4 Axis Unipolar Chopper control.

- Individual OR simultaneous control of 2/4 Phase Stepper Motors.

- Accepts 5, 6, or 8 wire stepper motors only.

4 wire types are not usable.

- 42VDC maximum input voltage, 12VDC minimum input voltage. 24VDC Minimum Recommended Voltage.

- 3.0 Amps Maximum per Phase, 500ma (.5A) minimum. Each axis adjustable throughout this range.

- 1/1, 1/2, 1/4, 1/8, and 1/16 Microstepping.

- Step and Direction Control.

- Idle Current Reduction to 50%

when idle for 10 seconds. Can change this time delay.

- Built In Protection Circuit to

help against blown chips on stepper motor short or open

connections.

- 3.7" by 6.8" double sided with top silkscreen and thru plated holes

and lead free solder PCB. (RoHS compliant).

- Power On Reset.

- On board voltage regulation for 5-volt logic with 24VDC cooling fan from motor power supply.

- On board connections for home and limit switches with 10K pullup resistor provided to each. No need for a separate "break out" board.

- Minimum of components to make assembly fast and easy!

- Works with Step and Direction software such as DeskNC, TurboCNC, Mach2, etc

|

|

|

|

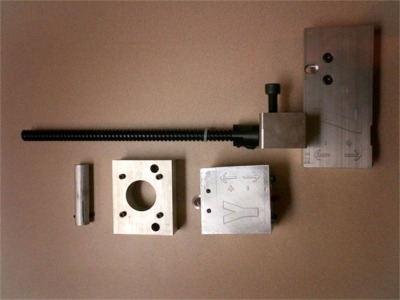

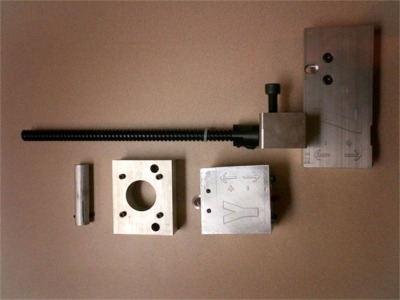

A kit with three NEMA23 motor mounts, thrust bearings for each axis, shaft collars, lovejoy spider motor couplings, a BALLSCREW for the Z axis, and metric cap screws.

from www.cncfusion.com

|

|

|

|

2006-10-20 This is the controler box that is ready for use:

|

|

|

|

|

This is the mill that is going to be converted. As you see I 'borrowed' our guest room.

|

|

|

|

2006-12-02 Finally ready.

Of course there are always things that can be done better: for example I will upgrade the X and Y axis.

But for now I', happy. My first real build, was a mount for my Dremel. With it's 22000 RPM I can now

mill and drill PCB-boards as well.

|

|